Typical usage Scenarios and Examples

Choose a task from the list below. For more details on alternative

options, follow the links to the individual tools being used.

Note that by default it is assumed that ICC profile have the file

extension .icm, but that on

Apple OS X and Unix/Linux platforms, the .icc extension is expected and should be used.

Image dependent gamut

mapping using device links

Soft Proofing Link

Profiling Displays

Argyll supports adjusting, calibrating and profiling of displays

using one of a number of instruments - see instruments for a current list.

Adjustment and calibration are prior steps to profiling, in which

the display is adjusted using it's screen controls, and then

per channel lookup tables are created to make it meet a well behaved

response of the desired type. The process following that of

creating a display profile is then similar to that of all other

output devices :- first a set of device colorspace test values needs

to be created to exercise the display, then these values need to be

displayed, while taking measurements of the resulting colors using

the instrument. Finally, the device value/measured color values need

to be converted into an ICC profile.

Checking you can access your display

You might first want to check that you are accessing and can

calibrate your display. You can do this using the dispwin

tool. If you just run dispwin it will create a test

window and run through a series of test colors before checking that

the VideoLUT can be accessed by the display. If you invoke the usage

for dispwin (by giving it

an unrecognized option, e.g. -?)

then it will show a list of available displays next to the -d

flag. Make sure that you are accessing the display you intend to

calibrate and profile, and that the VideoLUT is effective (the -r flag can be used to just run

the VideoLUT test). You can also try clearing the VideoLUTs using

the -c flag, and loading a

deliberately strange looking calibration strange.cal that is provided in the Argyll ref directory.

Note that calibrating and/or profiling remote displays is possible using X11 or a web

browser (see -d option of

dispcal and dispread), or by using some external program to send

test colors to a display (see -C

and -M options of dispcal

and dispread), but you may want to refer to Calibrating

and profiling a display that doesn't have VideoLUT access.

Adjusting and Calibrating Displays

Please read What's the difference between

Calibration and Characterization ? if you are unclear as to

the difference .

The first step is to decide what the target should be for adjustment

and calibration. This boils down to three things: The desired

brightness, the desired white point, and the desired response curve.

The native brightness and white points of a display may be different

to the desired characteristics for some purposes. For instance, for

graphic arts use, it might be desirable to run with a warmer white

point of about 5000 degrees Kelvin, rather than the default display

white point of 6500 to 9000 Kelvin. Some LCD displays are too bright

to compare to printed material under available lighting, so it might

be desirable to reduce the maximum brightness.

You can run dispcal -r to check on how

your display is currently set up. (you may have to run this as dispcal

-yl

-r for an LCD display, or dispcal -yc -r for a

CRT display with most of the colorimeter instruments. If so, this

will apply to all of the following examples.)

Once this is done, dispcal can be run to

guide you through the display adjustments, and then calibrate it. By

default, the brightness and white point will be kept the same as the

devices natural brightness and white point. The default response

curve is a gamma of 2.4, except for Apple OS X systems prior to 10.6

where a gamma of 1.8 is the default. 2.4 is close to that of

many monitors, and close to that of the sRGB colorspace.

A typical calibration that leaves the brightness and white point

alone, might be:

dispcal -v TargetA

which will result in a "TargetA.cal" calibration file, that can then

be used during the profiling stage.

If the absolutely native response of the display is desired during

profiling, then calibration should be skipped, and the linear.cal

file from the "ref" directory used instead as the argument to the -k

flag of dispread.

Dispcal will display a test window in the middle of the

screen, and issue a series of instructions about placing the

instrument on the display. You may need to make sure that the

display cursor is not in the test window, and it may also be

necessary to disable any screensaver and powersavers before starting

the process, although both dispcal

and dispread will attempt

to do this for you. It's also highly desirable on CRT's, to clear

your screen of any white or bright background images or windows

(running your shell window with white text on a black background

helps a lot here.), or at least keep any bright areas away from the

test window, and be careful not to change anything on the display

while the readings are taken. Lots of bright images or windows can

affect the ability to measure the black point accurately, and

changing images on the display can cause inconsistency in the

readings, and leading to poor results. LCD displays seem to be less

influenced by what else is on the screen.

If dispcal is run without

arguments, it will provide a usage screen. The -c parameter allows selecting a

communication port for an instrument, or selecting the instrument

you want to use, and the -d option allows selecting

a target display on a multi-display system. On some multi-monitor

systems, it may not be possible to independently calibrate and

profile each display if they appear as one single screen to the

operating system, or if it is not possible to set separate video

lookup tables for each display. You can change the position and size

of the test window using the -P parameter. You can

determine how best to arrange the test window, as well as whether

each display has separate video lookup capability, by experimenting

with the dispwin tool.

For a more detailed discussion on interactively adjusting the

display controls using dispcal,

see dispcal-adjustment. Once

you have adjusted and calibrated your display, you can move on to

the next step.

When you have calibrated and profiled your display, you can keep it

calibrated using the dispcal -u

option.

Adjusting, calibrating and profiling in one

step.

If a simple matrix/shaper display profile is all that is desired, dispcal can be used to do this,

permitting display adjustment, calibration and profiling all in one

operation. This is done by using the dispcal -o

flag:

dispcal -v

-o TargetA

This will create both a TargetA.cal file, but also a TargetA.icm

file. See -o and -O for other variations.

For more flexibility in creating a display profile, the separate

steps of creating characterization test values using targen, reading them from the

display using dispread, and

then creating a profile using colprof

are used. The following steps illustrate this:

Profiling in several steps: Creating display

test values

If the dispcal has not been

used to create a display profile at the same time as adjustment and

calibration, then it can be used to create a suitable set of

calibration curves as the first step, or the calibration step can be

omitted, and the display cansimply be profiled.

The first step in profiling any output device, is to create a set of

device colorspace test values. The important parameters needed are:

- What colorspace does the device use ?

- How many test patches do I want to use ?

- What information do I already have about how the device

behaves ?

For a display device, the colorspace will be RGB. The number

of test patches will depend somewhat on what quality profile you

want to make, what type of profile you want to make, and how long

you are prepared to wait when testing the display.

At a minimum, a few hundred values are needed. A matrix/shaper type

of profile can get by with fewer test values, while a LUT based

profile will give better results if more test values are used. A

typical number might be 200-600 or so values, while 1000-2000 is not

an unreasonable number for a high quality characterization of a

display.

To assist the choice of test patch values, it can help to have a

rough idea of how the device behaves. This could be in the form of

an ICC profile of a similar device, or a lower quality, or previous

profile for that particular device. If one were going to make a very

high quality LUT based profile, then it might be worthwhile to make

up a smaller, preliminary shaper/matrix profile using a few hundred

test points, before embarking on testing the device with several

thousand.

Lets say that we ultimately want to make a profile for the device

"DisplayA", the simplest approach is to make a set of test values

that is independent of the characteristics of the particular device:

targen -v

-d3 -f500

DisplayA

If there is a preliminary or previous profile called "OldDisplay"

available, and we want to try creating a "pre-conditioned" set of

test values that will more efficiently sample the device response,

then the following would achieve this:

targen -v

-d3 -f500

-cOldDisplay.icm DisplayA

The output of targen will be the file DisplayA.ti1,

containing the device space test values, as well as expected CIE

values used for chart recognition purposes.

Profiling in several steps: Taking readings

from a display

First it is necessary to connect your measurement instrument to your

computer, and check which communication port it is connected to. In

the following example, it is assumed that the instrument is

connected to the default port 1, which is either the first USB

instrument found, or serial port found. Invoking dispread so as to

display the usage information (by using a flag -? or --) will list

the identified serial and USB ports, and their labels.

dispread -v

DisplayA

If we created a calibration for the display using dispcal, then we will want to use this

when we take the display readings (e.g. TargetA.cal from the

calibration example)..

dispread -v

-k TargetA.cal DisplayA

dispread will display a test window in the middle of the

screen, and issue a series of instructions about placing the

instrument on the display. You may need to make sure that the

display cursor is not in the test window, and it may also be

necessary to disable any screensaver before starting the process.

Exactly the same facilities are provided to select alternate

displays using the -d

parameter, and an alternate location and size for the test window

using the -P parameter as

with dispcal.

Profiling in several steps: Creating a display

profile

There are two basic choices of profile type for a display, a

shaper/matrix profile, or a LUT based profile. They have different

tradeoffs. A shaper/matrix profile will work well on a well behaved

display, that is one that behaves in an additive color manner, will

give very smooth looking results, and needs fewer test points to

create. A LUT based profile on the other hand, will model any

display behaviour more accurately, and can accommodate gamut mapping

and different intent tables. Often it can show some unevenness and

contouring in the results though.

To create a matrix/shaper profile, the following suffices:

colprof -v

-D"Display A" -qm

-as DisplayA

For a LUT based profile, where gamut mapping is desired, then a

source profile will need to be provided to define the source gamut.

For instance, if the display profile was likely to be linked to a

CMYK printing source profile, say "swop.icm" or "fogra39l.icm", then

the following would suffice:

colprof -v

-D"Display A" -qm

-S

fogra39l.icm -cpp -dmt DisplayA

A fallback to using a specific source profile/gamut is to use a

general compression percentage as a gamut mapping:

colprof -v

-D"Display A" -qm

-S 20 -cpp -dmt DisplayA

Make sure you check the delta E report at the end of the profile

creation, to see if the sample data and profile is behaving

reasonably.

If a calibration file was used with dispread,

then it will be converted to a vcgt tag in the profile, so that the

operating system or other system color tools load the lookup curves

into the display hardware, when the profile is used.

Installing a display profile

dispwin provides a convenient way of

installing a profile as the default system profile for the chosen

display:

dispwin -I

DisplayA.icm

This also sets the display to the calibration contained in the

profile. If you want to try out a calibration before installing the

profile, using dispwin without the -I

option will load a calibration (ICC profile or .cal file) into the

current display.

Some systems will automatically set the display to the calibration

contained in the installed profile (ie. OS X), while on other

systems (ie. MSWindows and Linux/X11) it is necessary to use some

tool to do this. On MSWindows XP you could install the

optional Microsoft Color Control Panel Applet for Windows XP

available for download from Microsoft to do this, but NOTE however that it seems to

have a bug, in that it

sometimes associates the profiles with the wrong monitor entry. Other

display calibration tools will often install a similar tool, so

beware of there being multiple, competing programs. [ Commonly these

will be in your Start->Programs->Startup folder. ]

On Microsoft Vista, you need to use dispwin -L or some other tool to

load the installed profiles calibration at startup.

To use dispwin to load the installed profiles calibration to the

display, use

dispwin -L

As per usual, you can select the appropriate display using the -d flag.

This can be automated on MSWindows and X11/Linux by adding this

command to an appropriate startup script.

More system specific details, including how to create such startup

scripts are here.

If you are using Microsoft Vista,

there is a known bug in

Vista that resets the calibration every time a fade-in effect is

executed, which happens if you lock and unlock the computer, resume

from sleep or hibernate, or User Access Control is activated. Using

dispwin -L

may not restore the calibration, because Vista filters out setting

(what it thinks) is a calibration that is already loaded. Use dispwin -c -L

as a workaround, as this will first clear the calibration, then

re-load the current calibration.

On X11/Linux systems, you could try adding dispwin

-L to your ~/.config/autostart file, so that your window

manager automatically sets calibration when it starts. If you are

running XRandR 1.2, you might consider running the experimental dispwin -E in the background, as in its

"daemon" mode it will update the profile and calibration in response

to any changes in the the connected display.

Expert tips when measuring displays:

Sometimes it can be difficult to get good quality, consistent and

visually relevant readings from displays, due to various practical

considerations with regard to instruments and the displays

themselves. Argyll's tools have some extra options that may assist

in overcoming these problems.

If you are using an Eye-One Pro or ColorMunki spectrometer, then you

may wish to use the high resolution

spectral mode (-H).

This may be better at capturing the often narrow wavelength peaks

that are typical of display primary colors.

All instruments depend on silicon sensors, and such sensors generate

a temperature dependant level of noise ("dark noise") that is

factored out of the measurements by a dark or black instrument

calibration. The spectrometers in particular need this calibration

before commencing each set of measurements. Often an instrument will

warm up as it sits on a display, and this warming up can cause the

dark noise to increase, leading to inaccuracies in dark patch

measurements. The longer the measurement takes, the worse this

problem is likely to be. One way of addressing this is to

"acclimatise" the instrument before commencing measurements by

placing it on the screen in a powered up state, and leaving it for

some time. (Some people leave it for up to an hour to acclimatise.).

Another approach is to try and compensate

for dark calibration changes (-Ib)

by doing on the fly calibrations during the measurements, based on

the assumption that the black level of the display itself won't

change significantly.

Some displays take a long time to settle down and stabilise. The is

often the case with LCD (Liquid Crystal) displays that use

fluorescent back lights, and these sorts of displays can change in

brightness significantly with changes in temperature. One way of

addressing this is to make sure that the display is given adequate

time to warm up before measurements. Another approach is to try and

compensate for display white level

(-Iw) changes by doing on

the fly calibrations during the measurements. Instrument black level

drift and display white level drift can be combined (-Ibw).

Colorimeter instruments make use of physical color filters that

approximate the standard observer spectral sensitivity curves.

Because these filters are not perfectly accurate, the manufacturer

calibrates the instrument for typical displays, which is why you

have to make a selection between CRT (Cathode Ray Tube) and LCD

(Liquid Crystal Display) modes. If you are measuring a display that

has primary colorants that differ significantly from those typical

displays, (ie. you have a Wide Gamut Display), then you may

get disappointing results with a Colorimeter. One way of addressing

this problem is to use a Colorimeter

Correction Matrix. These are specific to a particular

Colorimeter and Display make and model combination, although a

matrix for a different but similar type of display may give better

results than none at all. A list of contributed ccmx files is here.

Calibrating and profiling a display that

doesn't have VideoLUT access.

In some situation there is no access to a displays VideoLUT

hardware, and this hardware is what is usually used to implement

display calibration. This could be because the display is being

accessed via a web server, or because the driver or windowing

system doesn't support VideoLUT access.

There are two basic options in this situation:

1) Don't attempt to calibrate, just profile the display.

2) Calibrate, but incorporate the calibration in some other

way in the workflow.

The first case requires nothing special - just skip calibration

(see the previous section Profiling in several

steps: Creating display test values).

In the second case, there are three choices:

2a) Use dispcal to create a calibration and a quick profile

that incorporates the calibration into the profile.

2b) Use dispcal to create the calibration, then dispread and

colprof to create a profile, and then incorporate the calibration

into the profile using applycal.

2c) Use dispcal to create the calibration, then dispread and

colprof to create a profile, and then apply the calibration after

the profile in a cctiff workflow.

The first case requires nothing special, use dispcal in a normal

fashioned with the -o

option to generate a quick profile.The profile created will not contain a 'vcgt'

tag, but instead will have the calibration curves incorporated

into the profile itself. If calibration parameters are chosen that

change the displays white point or brightness, then this will

result in a slightly unusual profile that has a white point that

does not correspond with device R=G=B=1.0. Some systems may not

cope properly with this type of profile, and a general shift in

white point through such a profile can create an odd looking

display if it is applied to images but not to other elements on

the display say as GUI decoration elements or other application

windows.

In the second case, the calibration file created using dispcal

should be provided to dispread using the -K flag:

dispread -v

-K TargetA.cal DisplayA

Create the profile as

usual using colprof. but note that colprof will ignore the

calibration, and that no 'vcgt' tag will be added to the profile.

You can then use applycal to combine

the calibration into the profile. Note that the resulting profile

will be slightly unusual, since the profile is not made completely

consistent with the effects of the calibration, and the device

R=G=B=1.0 probably not longer corresponds with the PCS white or

the white point.

In the third case, the same procedure as above is used to create a

profile, but the calibration is applied in a raster transformation

workflow explicitly, e.g.:

cctiff SourceProfile.icm DisplayA.icm DisplayA.cal

infile.tif outfile.tif

or

cctiff SourceProfile.icm DisplayA.icm DisplayA.cal

infile.jpg outfile.jpg

Profiling Scanners and other input devices

such as cameras

Because a scanner or camera is an input device, it is necessary to

go about profiling it in quite a different way to an output device.

To profile it, a test chart is needed to exercise the input device

response, to which the CIE values for each test patch is known.

Generally standard reflection or transparency test charts are used

for this purpose.

Types of test charts

The most common and popular test chart for scanner profiling is the

IT8.7/2 chart. This is a standard format chart generally reproduced

on photographic film, containing about 264 test patches.

An accessible and affordable source of such targets is Wolf Faust a

www.coloraid.de.

Another source is LaserSoft www.silverfast.com.

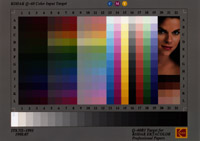

The Kodak Q-60 Color Input Target is also a typical example:

A very simple chart that is widely available is the Macbeth

ColorChecker chart, although it contains only 24 patches and

therefore is probably not ideal for creating profiles:

Other popular charts are the X-Rite/GretagMacbeth ColorChecker DC

and ColorChecker

SG charts:

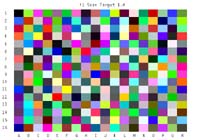

The GretagMacbeth Eye-One Pro Scan Target 1.4 can also be used:

Also supported is the HutchColor

HCT :

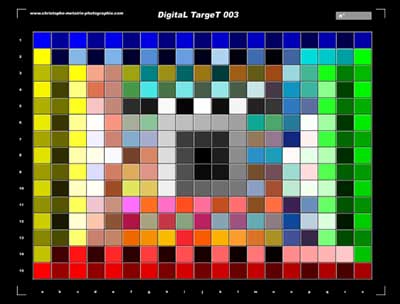

and Christophe

Métairie's Digital TargeT 003, Christophe

Métairie's Digital Target - 4 , and Christophe

Métairie's Digital Target - 7:

and the LaserSoft

Imaging DCPro Target:

The Datacolor SpyderCheckr:

The Datacolor SpyderCheckr24:

One of the QPcard's:

QPcard

201: QPcard

202:

Taking readings from a scanner or camera

The test chart you are using needs to be placed on the scanner, and

the scanner needs to be configured to a suitable state, and restored

to that same state when used subsequently with the resulting

profile. For a camera, the chart needs to be lit in a controlled and

even manner using the light source that will be used for subsequent

photographs, and should be shot so as to minimise any geometric

distortion, although the scanin -p flag

may be used to compensate for some degree of distortion. As with any

color profiling task, it is important to setup a known and

repeatable image processing flow, to ensure that the resulting

profile will be usable.

The chart should be captured and saved to a TIFF format file. I will

assume the resulting file is called scanner.tif. The raster file

need only be roughly cropped so as to contain the test chart

(including the charts edges).

The second step is to extract the RGB values from the scanner.tif

file, and match then to the reference CIE values. To locate the

patch values in the scan, the scanin tool needs to be given

a template .cht file that

describes the features of the chart, and how the test patches are

labeled. Also needed is a file containing the CIE values for each of

the patches in the chart, which is typically supplied with the

chart, available from the manufacturers web site, or has been

measured using a spectrometer.

For an IT8.7/2 chart, this is the

ref/it8.cht file

supplied with Argyll, and the manufacturer will will supply

an individual or batch average file along with the chart

containing this information, or downloadable from their web site.

For instance, Kodak Q60 target reference files are

here.

NOTE that the reference file for the IT8.7/2 chart supplied with

Monaco EZcolor can be

obtained by unzipping the .mrf file. (You may have to make a copy

of the file with a .zip extension to do this.)

For the ColorChecker 24 patch chart, the

ref/ColorChecker.cht file

should be used, and there is also a

ref/ColorChecker.cie file provided that is based

on the manufacturers reference values for the chart. You can also

create your own reference file using an instrument and chartread,

making use of the chart reference file

ref/ColorChecker.ti2:

chartread -n

ColorChecker.ti2

Note that due to the small number of patches, a profile created

from such a chart is not likely to be very detailed.

For the ColorChecker DC chart, the

ref/ColorCheckerDC.cht file should be used, and

there will be a ColorCheckerDC reference file supplied by

X-Rite/GretagMacbeth with the chart.

The ColorChecker SG is relatively expensive, but is preferred by

many people because (like the ColorChecker and ColorCheckerDC) its

colors are composed of multiple different pigments, giving it

reflective spectra that are more representative of the real world,

unlike many other charts that are created out of combination of 3

or 4 colorants.

A limited CIE reference file is available from X-Rite

here,

but it is not in the usual CGATS format. To convert it to a CIE

reference file useful for

scanin,

you will need to edit the X-Rite file using a

plain text editor,

first deleting everything before the line starting with "A1" and

everything after "N10", then prepending

this

header, and appending

this footer,

making sure there are no blank lines inserted in the process. Name

the resulting file

ColorCheckerSG.cie.

There are reports that X-Rite have experimented with different ink

formulations for certain patches, so the above reference may not

be as accurate as desired, and it is preferable to measure your

own chart using a spectrometer, if you have the capability.

If you do happen to have access to a more comprehensive instrument

measurement of the ColorChecker SG, or you have measured it

yourself using chart reading software other than ArgyllCMS, then

you

may need to

convert the reference information from spectral only

ColorCheckerSG.txt file to CIE

value

ColorCheckerSG.cie

reference file, follow the following steps:

txt2ti3

ColorCheckerSG.txt ColorCheckerSG

spec2cie

ColorCheckerSG.ti3 ColorCheckerSG.cie

For the Eye-One Pro Scan Target 1.4 chart, the

ref/i1_RGB_Scan_1.4.cht

file should be used, and as there is no reference file

accompanying this chart, the chart needs to be read with an

instrument (usually the Eye-One Pro). This can be done using

chartread, making use of the chart reference file

ref/i1_RGB_Scan_1.4.ti2:

chartread -n

i1_RGB_Scan_1.4

and then rename the resulting

i1_RGB_Scan_1.4.ti3

file to

i1_RGB_Scan_1.4.cie

For the HutchColor HCT chart, the

ref/Hutchcolor.cht

file should be used, and the reference

.txt file downloaded from the HutchColor website.

For the Christophe Métairie's Digital TargeT 003 chart with 285

patches, the

ref/CMP_DT_003.cht

file should be used, and the cie reference

files come with the chart.

For the Christophe Métairie's Digital Target-4 chart with 570

patches, the

ref/CMP_Digital_Target-4.cht

file should be used, and the cie reference

files come with the chart.

For the Christophe Métairie's Digital Target-7 chart with 570

patches, the

ref/CMP_Digital_Target-7.cht

file should be used, and the spectral .txt file should be

converted to a cie reference file:

txt2ti3

DT7_XXXXX_Spectral.txt temp

spec2cie temp.ti3

DT7_XXXXX.cie

For the LaserSoft DCPro chart, the

ref/LaserSoftDCPro.cht file should be used, and

reference

.txt file

downloaded from the

Silverfast

website.

For the Datacolor SpyderCheckr, the

ref/SpyderChecker.cht file should be used, and a

reference

ref/SpyderChecker.cie

file made from measuring a sample chart is also available.

Alternately you could create your own reference file by

transcribing the

values

on the Datacolor website.

For the Datacolor SpyderCheckr, the

ref/SpyderChecker24.cht file should be used, and a

reference

ref/SpyderChecker24.cie

file made from measuring a sample chart is also available.

Alternately you could create your own reference file by

transcribing the

values

on the Datacolor website.

For the QPCard 201, the

ref/QPcard_201.cht

file should be used, and a reference

ref/QPcard_201.cie file made from measuring a

sample chart is also available.

For the QPCard 202, the

ref/QPcard_202.cht

file should be used, and a reference

ref/QPcard_202.cie file made from measuring a

sample chart is also available.

For any other type of chart, a chart recognition template file will

need to be created (this is beyond the scope of the current

documentation, although see the .cht_format

documentation).

To create the scanner .ti3 file, run the scanin tool as

follows (assuming an IT8 chart is being used):

scanin -v scanner.tif It8.cht It8ref.txt

"It8ref.txt" or "It8ref.cie" is assumed to be the name of the CIE

reference file supplied by the chart manufacturer. The resulting

file will be named "scanner.ti3".

scanin will process 16 bit

per component .tiff files, which (if the scanner is capable of

creating such files), may improve the quality of the profile.

If you have any doubts about the correctness of the chart

recognition, or the subsequent profile's delta E report is unusual,

then use the scanin diagnostic flags -dipn

and examine the diag.tif

diagnostic file, to make sure that the patches are identified and

aligned correctly. If you have problems getting good automatic

alignment, then consider doing a manual alignment by locating the

fiducial marks on your scan, and feeding them into scanin -F parameters. The fiducial marks should

be listed in a clockwise direction starting at the top left.

Creating a scanner or camera input profile

Similar to a display profile, an input profile can be either a

shaper/matrix or LUT based profile. Well behaved input devices will

probably give the best results with a shaper/matrix profile, and

this may also be the best choice if your test chart has a small or

unevenly distributed set of test patchs (ie. the IT8.7.2). If a

shaper/matrix profile is a poor fit, consider using a LUT type

profile.

When creating a LUT type profile, there is the choice of XYZ or

L*a*b* PCS (Device independent, Profile Connection Space). Often for

input devices, it is better to choose the XYZ PCS, as this may be a

better fit given that input devices are usually close to being

linearly additive in behaviour.

If the purpose of the input profile is to use it as a substitute for

a colorimeter, then the -u flag should be used to avoid

clipping values above the white point. Unless the shaper/matrix type

profile is a very good fit, it is probably advisable to use a LUT

type profile in this situation.

To create a matrix/shaper profile, the following suffices:

colprof -v

-D"Scanner A"

-qm -as scanner

For an XYZ PCS LUT based profile then the following would be used:

colprof -v

-D"Scanner A" -qm

-ax scanner

For the purposes of a poor mans colorimeter, the following would

generally be used:

colprof -v

-D"Scanner A" -qm

-ax -u scanner

Make sure you check the delta E report at the end of the profile

creation, to see if the sample data and profile is behaving

reasonably. Depending on the type of device, and the consistency of

the readings, average errors of 5 or less, and maximum errors of 15

or less would normally be expected. If errors are grossly higher

than this, then this is an indication that something is seriously

wrong with the device measurement, or profile creation.

If profiling a camera in RAW mode, then there may be some

advantage in creating a pure matrix only profile, in which it is

assumed that the camera response is completely linear. This may

reduce extrapolation artefacts. If setting the white point will be

done in some application, then it may also be an advantage to use

the -u flag and avoid

setting the white point to that of the profile chart:

colprof -v

-D"Camera" -qm

-am -u scanner

Profiling Printers

The overall process is to create a set of device measurement target

values, print them out, measure them, and then create an ICC profile

from the measurements. If the printer is an RGB based printer, then

the process is only slightly more complicated than profiling a

display. If the printer is CMYK based, then some additional

parameters are required to set the total ink limit (TAC) and

black generation curve.

Creating a print profile test chart

The first step in profiling any output device, is to create a set of

device colorspace test values. The important parameters needed are:

- What colorspace does the device use ?

- How many test patches do I want to use/what paper size do I

want to use ?

- What instrument am I going to use to read the patches ?

- If it is a CMYK device, what is the total ink limit ?

- What information do I already have about how the device

behaves ?

Most printers running through simple drivers will appear as if they

are RGB devices. In fact there is no such thing as a real RGB

printer, since printers use white media and the colorant must

subtract from the light reflected on it to create color, but the

printer itself turns the incoming RGB into the native print

colorspace, so for this reason we will tell targen to use the "Print

RGB" colorspace, so that it knows that it's really a subtractive

media. Other drivers will drive a printer more directly, and will

expect a CMYK profile. [Currently Argyll is not capable of creating

an ICC profile for devices with more colorants than CMYK. When this

capability is introduced, it will by creating an additional

separation profile which then allows the printer to be treated as a

CMY or CMYK printer.] One way of telling what sort of profile is

expected for your device is to examine an existing profile for that

device using iccdump.

The number of test patches will depend somewhat on what quality

profile you want to make, how well behaved the printer is, as well

as the effort needed to read the number of test values. Generally it

is convenient to fill a certain paper size with the maximum number

of test values that will fit.

At a minimum, for an "RGB" device, a few hundred values are needed

(400-1000). For high quality CMYK profiles, 1000-3000 is not an

unreasonable number of patches.

To assist the determination of test patch values, it can help to

have a rough idea of how the device behaves, so that the device test

point locations can be pre-conditioned. This could be in the form of

an ICC profile of a similar device, or a lower quality, or previous

profile for that particular device. If one were going to make a very

high quality Lut based profile, then it might be worthwhile to make

up a smaller, preliminary shaper/matrix profile using a few hundred

test points, before embarking on testing the device with several

thousand.

The documentation for the targen tool

lists a table

of paper sizes and number of patches for typical situations.

For a CMYK device, a total ink limit usually needs to be specified.

Sometimes a device will have a maximum total ink limit set by its

manufacturer or operator, and some CMYK systems (such as chemical

proofing systems) don't have any limit. Typical printing devices

such as Xerographic printers, inkjet printers and printing presses

will have a limit. The exact procedure for determining an ink limit

is outside the scope of this document, but one way of going about

this might be to generate some small (say a few hundred patches)

with targen & pritntarg with different total ink limits, and

printing them out, making the ink limit as large as possible without

striking problems that are caused by too much ink.

Generally one wants to use the maximum possible amount of ink to

maximize the gamut available on the device. For most CMYK devices,

an ink limit between 200 and 400 is usual, but and ink limit of 250%

or over is generally desirable for reasonably dense blacks and dark

saturated colors. And ink limit of less than 200% will begin to

compromise the fully saturated gamut, as secondary colors (ie

combinations of any two primary colorants) will not be able to reach

full strength.

Once an ink limit is used in printing the characterization test

chart for a device, it becomes a critical parameter in knowing what

the characterized gamut of the device is. If after printing the test

chart, a greater ink limit were to be used, the the software would

effectively be extrapolating the device behaviour at total ink

levels beyond that used in the test chart, leading to inaccuracies.

Generally in Argyll, the ink limit is established when creating the

test chart values, and then carried through the profile making

process automatically. Once the profile has been made however, the

ink limit is no longer recorded, and you, the user, will have to

keep track of it if the ICC profile is used in any program than

needs to know the usable gamut of the device.

Lets consider two devices in our examples, "PrinterA" which is an

"RGB" device, and "PrinterB" which is CMYK, and has a target ink

limit of 250%.

The simplest approach is to make a set of test values that is

independent of the characteristics of the particular device:

targen -v

-d2 -f1053

PrinterA

targen -v

-d4 -l260

-f1053 PrinterB

The number of patches chosen here happens to be right for an A4

paper size being read using a Spectroscan instrument. See the table in the targen documentation for some other

suggested numbers.

If there is a preliminary or previous profile called "OldPrinterA"

available, and we want to try creating a "pre-conditioned" set of

test values that will more efficiently sample the device response,

then the following would achieve this:

targen -v

-d2 -f1053

-c OldPrinterA PrinterA

targen -v

-d4 -l260

-f1053 -c

OldPrinterB PrinterB

The output of targen will be the file PrinterA.ti1 and

PrinterB.ti1 respectively, containing the device space test values,

as well as expected CIE values used for chart recognition purposes.

Printing a print profile test chart

The next step is turn the test values in to a PostScript or TIFF

raster test file that can printed on the device. The basic

information that needs to be supplied is the type of instrument that

will be used to read the patches, as well as the paper size it is to

be formatted for.

For an X-Rite DTP41, the following would be typical:

printtarg -v

-i41 -pA4

PrinterA

For a Gretag Eye-One Pro, the following would be typical:

printtarg -v

-ii1 -pA4

PrinterA

For using with a scanner as a colorimeter, the Gretag Spectroscan

layout is suitable, but the -s flag

should be used so as to generate a layout suitable for scan

recognition, as well as generating the scan recognition template

files. (You probably want to use less patches with targen, when using the printtarg -s flag, e.g. 1026

patches for an A4R page, etc.) The following would be typical:

printtarg -v

-s -iSS

-pA4R PrinterA

printtarg reads the PrinterA.ti1 file, creates a

PrinterA.ti2 file containing the layout information as well as the

device values and expected CIE values, as well as a PrinterA.ps file

containing the test chart. If the -s

flag is used, one or more PrinterA.cht files is created to allow the

scanin program to recognize the chart.

To create TIFF raster files rather than PostScript, use the -t

flag.

GSview is a good program to

use to check what the PostScript file will look like, without

actually printing it out. You could also use Photoshop or ImageMagick for this purpose.

The last step is to print the chart out.

Using a suitable PostScript or raster file printing program,

downloader, print the chart. If you are not using a TIFF test chart,

and you do not have a PostScript capable printer, then an

interpreter like GhostScript or even Photoshop could be used to

rasterize the file into something that can be printed. Note that it

is important that the PostScript interpreter or TIFF printing

application and printer configuration is setup for a device

profiling run, and that any sort of color conversion of color

correction be turned off so that the device values in the PostScript

or TIFF file are sent directly to the device. If the device has a

calibration system, then it would be usual to have setup and

calibrated the device before starting the profiling run, and to

apply calibration to the chart values. If Photoshop was to be used,

then either the chart needs to be a single page, or separate .eps or

.tiff files for each page should be used, so that they can be

converted and printed one at a time (see the -e and -t

flags).

Reading a print test chart using an instrument

Once the test chart has been printed, the color of the patches needs

to be read using a suitable instrument.

Several different instruments are currently supported, some that

need to be used patch by patch, some read a strip at a time, and

some read a sheet at a time. See instruments

for a current list.

The instrument needs to be connected to your computer before running

the chartread command. Both serial

port and USB connected Instruments are supported. A serial port to

USB adapter might have to be used if your computer doesn't have any

serial ports, and you have a serial interface connected instrument.

If you run chartread so as to print

out its usage message (ie. by using a -? or --

flags), then it will list any identified serial ports or USB

connected instruments, and their corresponding number for the -c option. By default, chartread will try to connect to the

first available USB instrument, or an instrument on the first serial

port.

The only arguments required is to specify the basename of the .ti2

file. If a non-default serial port is to be used, then the -c option would also be

specified.

e.g. for a Spectroscan on the second port:

chartread -c2

PrinterA

For a DTP41 to the default serial port:

chartread

PrinterA

chartread will interactively

prompt you through the process of reading each sheet or strip. See chartread for more details on the

responses for each type of instrument. Continue with Creating a printer profile.

Reading a print test chart using a scanner or

camera

Argyll supports using a scanner or even a camera as a substitute for

a colorimeter. While a scanner or camera is no replacement for a

color measurement instrument, it may give acceptable results in some

situations, and may give better results than a generic profile for a

printing device.

The main limitation of the scanner-as-colorimeter approach are:

* The scanner dynamic range and/or precision may not match the

printers or what is required for a good profile.

* The spectral interaction of the scanner test chart and printer

test chart with the scanner spectral response can cause color

errors.

* Spectral differences caused by different black amounts in the

print test chart can cause color errors.

* The scanner reference chart gamut may be much smaller than the

printers gamut, making the scanner profile too inaccurate to be

useful.

As well as some of the above, a camera may not be suitable if it

automatically adjusts exposure or white point when taking a picture,

and this behavior cannot be disabled.

The end result is often a profile that has a noticeable color cast,

compared to a profile created using a colorimeter or spectrometer.

It is assumed that you have created a scanner or camera profile

following the procedure

outline above. For best possible results it is advisable to both

profile the scanner or camera, and use it in scanning the printed

test chart, in as "raw" mode as possible (i.e. using 16 bits per

component images, if the scanner or camera is capable of doing so;

not setting white or black points, using a fixed exposure etc.). It

is generally advisable to create a LUT type input profile, and use

the -u

flag to avoid clipping scanned value whiter than the input

calibration chart.

Scan or photograph your printer chart (or charts) on the scanner or

camera previously profiled. The

scanner or camera must be configured and used exactly the same

as it was when it was profiled.

I will assume the resulting scan/photo input file is called PrinterB.tif (or PrinterB1.tif, PrinterB2.tif etc. in the case

of multiple charts). As with profiling the scanner or camera, the

raster file need only be roughly cropped so as to contain the test

chart.

The scanner recognition files created when printtarg was run is assumed to

be called PrinterB.cht.

Using the scanner profile created previously (assumed to be called scanner.icm), the printer test

chart scan patches are converted to CIE values using the scanin tool:

scanin -v -c PrinterB.tif

PrinterB.cht scanner.icm PrinterB

If there were multiple test chart pages, the results would be

accumulated page by page using the -ca

option, ie., if there were 3 pages:

scanin -v -c PrinterB1.tif

PrinterB1.cht scanner.icm PrinterB

scanin -v -ca PrinterB2.tif

PrinterB2.cht scanner.icm PrinterB

scanin -v -ca PrinterB3.tif

PrinterB3.cht scanner.icm PrinterB

Now that the PrinterB.ti3

data has been obtained, the profile continue in the next section

with Creating a printer profile.

If you have any doubts about the correctness of the chart

recognition, or the subsequent profile's delta E report is unusual,

then use the scanin diagnostic flags -dipn

and examine the diag.tif

diagnostic file.

Creating a printer profile

Creating an RGB based printing profile is very similar to creating a

display device profile. For a CMYK printer, some additional

information is needed to set the black generation.

Where the resulting profile will be used conventionally (ie. using collink -s,

or cctiff or most other "dumb" CMMs) it

is important to specify that gamut mapping should be computed for

the output (B2A) perceptual and saturation tables. This is done by

specifying a device profile as the parameter to the colprof -S

flag. When you intend to create a "general use" profile, it can be a

good technique to specify the source gamut as the opposite type of

profile to that being created, i.e. if a printer profile is being

created, specify a display profile (e.g. sRGB) as the source gamut.

If a display profile is being created, then specify a printer

profile as the source (e.g. Figra, SWOP etc.). When linking to

the profile you have created this way as the output profile, then

use perceptual intent if the source is the opposite type, and

relative colorimetric if it is the same type.

"Opposite type of profile" refers to the native gamut of the device,

and what its fundamental nature is, additive or subtractive. An

emissive display will have additive primaries (R, G & B), while

a reflective print, will have subtractive primaries (C, M, Y &

possibly others), irrespective of what colorspace the printer is

driven in (a printer might present an RGB interface, but internally

this will be converted to CMY, and it will have a CMY type of

gamut). Because of the complimentary nature of additive and

subtractive device primary colorants, these types of devices have

the most different gamuts, and hence need the most gamut mapping to

convert from one colorspace to the other.

If you are creating a profile for a specific purpose, intending to

link it to a specific input profile, then you will get the best

results by specifying that source profile as the source gamut.

If a profile is only going to be used as an input profile, or is

going to be used with a "smart" CMM (e.g. collink

-g or -G),

then

it can save considerable processing time and space if the -b flag is

used, and the -S flag not used.

For an RGB printer intended to print RGB originals, the following

might be a typical profile usage:

colprof -v

-D"Printer A" -qm

-S sRGB.icm

-cmt -dpp

PrinterA

or if you intent to print from Fogra, SWOP or other standard CMYK

style originals:

colprof -v

-D"Printer A" -qm

-S

fogra39l.icm -cmt -dpp PrinterA

If you know what colorspace your originals are in, use that as the

argument to -S.

If your viewing environment for the display and print doesn't match

the ones implied by the -cmt and -dpp options, leave them out, and

evaluate what, if any appearance transformation is appropriate for

your environment at a later stage.

A fallback to using a specific source profile/gamut is to use a

general compression percentage as a gamut mapping:

colprof -v

-D"Printer A" -qm

-S 20 -cmt -dpp PrinterA

Make sure you check the delta E report at the end of the profile

creation, to see if the sample data and profile is behaving

reasonably. Depending on the type of device, and the consistency of

the readings, average errors of 5 or less, and maximum errors of 15

or less would normally be expected. If errors are grossly higher

than this, then this is an indication that something is seriously

wrong with the device measurement, or profile creation.

Choosing a black generation curve (and other

CMYK printer options)

For a CMYK printer, it would be normal to specify the type of black

generation, either as something simple, or as a specific curve. The

documentation in colprof for the

details of the options.

Note that making a good choice of black generation curve

can affect things such as: how robust neutrals are given printer

drift or changes in viewing lighting, how visible screening is, and

how smooth looking the B2A conversion is.

For instance, maximizing the level of K will mean that the neutral

colors are composed of greater amounts of Black ink, and black ink

retains its neutral appearance irrespective of printer behavior or

the spectrum of the illuminant used to view the print. On the other

hand, output which is dominantly from one of the color channels will

tend to emphasize the screening pattern and any unevenness (banding

etc.) of that channel, and the black channel in particular has the

highest visibility. So in practice, some balance between the levels

of the four channels is probably best, with more K if the screening

is fine and a robust neutral balance is important, or less K if the

screening is more visible and neutral balance is less critical. The

levels of K at the edges of the gamut of the device will be fixed by

the nature of the ink combinations that maximize the gamut (ie.

typically zero ink for light chromatic colors, some combination for

dark colors, and a high level of black for very dark near neutrals),

and it is also usually important to set a curve that smoothly

transitions to the K values at the gamut edges. Dramatic changes in

K imply equally dramatic changes in CMY, and these abrupt

transitions will reveal the limited precision and detail that can be

captured in a lookup table based profile, often resulting in a

"bumpy" looking output.

If you want to experiment with the various black generation

parameters, then it might be a good idea to create a preliminary

profile (using -ql -b -no, -ni and no -S),

and then used xicclu to explore the

effect of the parameters.

For instance, say we have our CMYK .ti3 file PrinterB.ti3. First we make a

preliminary profile called PrinterBt:

copy PrinterB.ti3 PrinterBt.ti3 (Use

"cp" on Linux or OSX of course.)

colprof -v

-qm -b -cmt -dpp

PrinterBt

Then see what the minimum black level down the neutral axis can be.

Note that we need to also set any ink limits we've decided on as

well (coloprof defaulting to 10% less than the value recorded in the

.ti3 file). In this example the test chart has a 300% total ink

limit, and we've decided to use 290%:

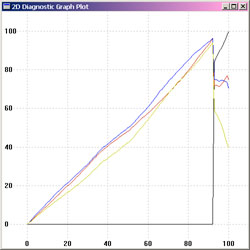

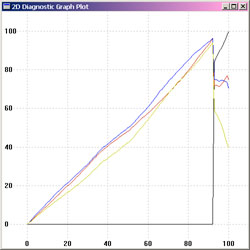

xicclu -g -kz -l290 -fif -ir PrinterBt.icm

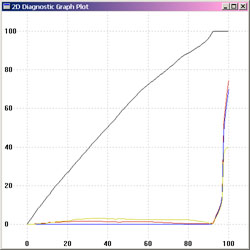

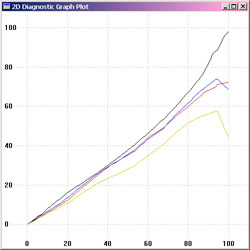

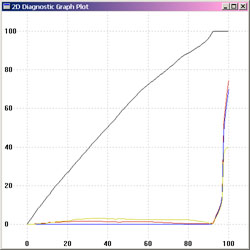

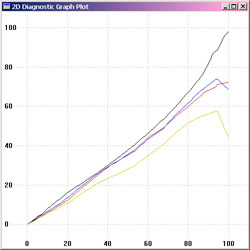

Which might be a graph something like this:

Note how the minimum black is zero up to 93% of the

white->black L* curve, and then jumps up to 87%. This is because

we've reached the total ink limit, and K then has to be substituted

for CMY, to keep the total under the total ink limit.

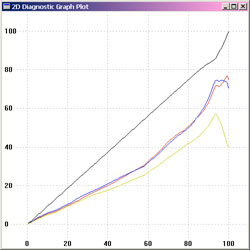

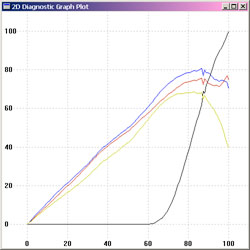

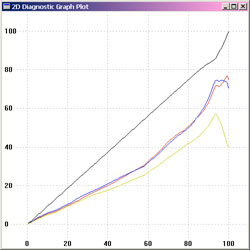

Then let's see what the maximum black level down the neutral axis

can be:

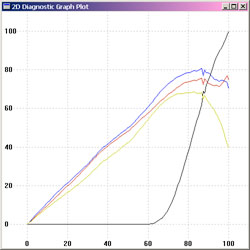

xicclu -g -kx -l290 -fif -ir PrinterBt.icm

Which might be a graph something like this:

Note how the CMY values are fairly low up to 93% of the

white->black L* curve (the low levels of CMY are helping set the

neutral color), and then they jump up. This is because we've reach

the point where black on it's own, isn't as dark as the color that

can be achieved using CMY and K. Because the K has a dominant effect

on the hue of the black, the levels of CMY are often fairly volatile

in this region.

Any K curve we specify must lie between the black curves of the

above two graphs.

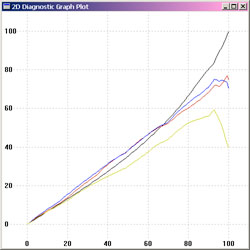

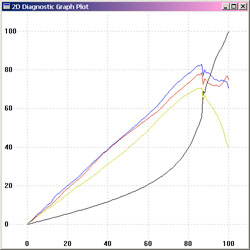

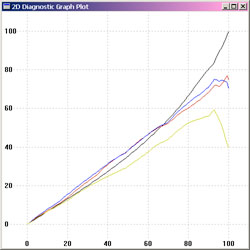

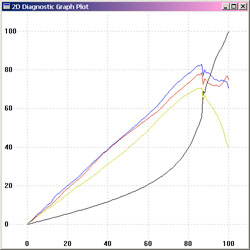

Let's say we'd like to chose a moderate black curve, one that aims

for about equal levels of CMY and K. We should also aim for it to be

fairly smooth, since this will minimize visual artefacts caused by

the limited fidelity that profile LUT tables are able to represent

inside the profile.

For minimum discontinuities we should aim for the curve to finish at

the point it has to reach to satisfy the total ink limit at 87%

curve and 93% black. For a first try we can simply set a straight

line to that point:

xicclu -g -kp 0 0 .93 .87 1.0 -l290 -fif -ir PrinterBt.icm

The black "curve" hits the 93%/87% mark well, but is a bit too far

above CMY, so we'll try making the black curve concave:

xicclu -g -kp 0 0 .93 .87

0.65 -l290 -fif -ir PrinterBt.icm

This looks just about perfect, so the the curve parameters can now

be used to generate our real profile:

colprof -v

-D"Printer B" -qm

-kp 0 0 .93

.87 0.65 -S sRGB.icm -cmt

-dpp PrinterB

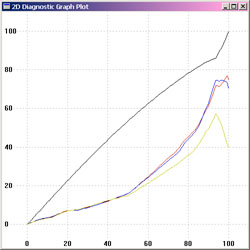

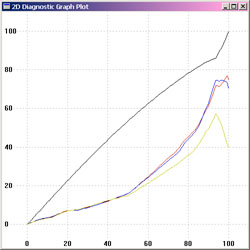

and the resulting B2A table black curve can be checked using xicclu:

xicclu -g -fb -ir PrinterB.icm

Examples of other inkings:

A smoothed zero black inking:

xicclu -g -kp 0 .7 .93 .87

1.0 -l290 -fif -ir PrinterBt.icm

A low black inking:

xicclu -g -kp 0 0 .93 .87

0.15 -l290 -fif -ir PrinterBt.icm

A high black inking:

xicclu -g -kp 0 0 .93 .87

1.2 -l290 -fif -ir PrinterBt.icm

Overriding the ink limit

Normally the total ink limit will be read from the PrinterB.ti3 file, and will be

set at a level 10% lower than the number used in creating the test

chart values using targen -l. If you

want to override this with a lower limit, then use the -l flag.

colprof -v

-D"Printer B" -qm

-S sRGB.icm

-cmt -dpp

-kr -l290

PrinterB

Make sure you check the delta E report at the end of the profile

creation, to see if the profile is behaving reasonably.

One way of checking that your ink limit is not too high, is to use "xicc -fif -ia" to check, by

setting different ink limits using the -l option, feeding Lab = 0 0 0 into it, and checking

the resulting black point. Starting with the ink limit used

with targen for the test

chart, reduce it until the black point starts to be affected. If it

is immediately affected by any reduction in the ink limit, then the

black point may be improved by increasing the ink limit used to

generate the test chart and then re-print and re-measuring it,

assuming other aspects such as wetness, smudging, spreading or

drying time are not an issue.

Calibrating Printers

Profiling creates a

description of how a device behaves, while calibration on the other hand is

intended to change

how a device behaves. Argyll has the ability to create per-channel

device space calibration curves for print devices, that can then be

used to improve the behavior of of the device, making a subsequent

profile fit the device more easily and also allow day to day

correction of device drift without resorting to a full re-profile.

NOTE: Because calibration

adds yet another layer to the way color is processed, it is

recommended that it not be attempted until the normal profiling

workflow is established, understood and verified.

Calibrated print workflows

There are two main workflows that printer calibration curves can be

applied to:

Workflow with native calibration

capability:

Firstly the printer itself may have the capability of using per

channel calibration curves. In this situation, the calibration

process will be largely independent of profiling. Firstly the

printer is configured to have both its color management and

calibration disabled (the latter perhaps achieved by loading linear

calibration curves), and a print calibration test chart that

consists of per channel color wedges is printed. The calibration

chart is read and the resulting .ti3 file converted into calibration

curves by processing it using printcal.

The calibration is then installed into the printer. Subsequent

profiling will be performed on the calibrated printer (ie. the profile test chart

will have the calibration curves applied to it by the printer, and

the resulting ICC profile will represent the behavior of the

calibrated printer.)

Workflow without native calibration

capability:

The second workflow is one in which the printer has no calibration

capability itself. In this situation, the calibration process will

have to be applied using the ICC color management tools, so careful

coordination with profiling is needed. Firstly the printer is

configured to have its color management disabled, and a print

calibration test chart that consists of per channel color wedges is

printed. The calibration chart is converted into calibration curves

by reading it and then processing the resultant .ti3 using printcal,. During the subsequent

profiling, the

calibration curves will need to be applied to the profile test chart

in the process of using printtarg.

Once the the profile has been created, then in subsequent printing

the calibration curves will need to be applied to an image being

printed either explicitly when using cctiff to apply color profiles and calibration, OR by creating a version of the

profile that has had the calibration curves incorporated into it

using the applycal tool.

The latter is useful when some CMM (color management module) other

than cctiff is being used.

Once calibration aim targets for a particular device and mode

(screening, paper etc.) have been established, then the printer can

be re-calibrated at any time to bring its per channel behavior back

into line if it drifts, and the new calibration curves can be

installed into the printer, or re-incorporated into the profile.

Creating a print calibration test chart

The first step is to create a print calibration test chart. Since

calibration only creates per-channel curves, only single channel

step wedges are required for the chart. The main choice is the

number of steps in each wedge. For simple fast calibrations perhaps

as few as 20 steps per channel may be enough, but for a better

quality of calibration something like 50 or more steps would be a

better choice.

Let's consider two devices in our examples, "PrinterA" which is an

"RGB" printer device, and "PrinterB" which is CMYK. In fact there is

no such thing as a real RGB printer, since printers use white media

and the colorant must subtract from the light reflected on it to

create color, but the printer itself turns the incoming RGB into the

native print colorspace, so for this reason we are careful to tell

targen to use the "Print RGB" colorspace, so that it knows to create

step wedges from media white to full colorant values.

For instance, to create a 50 steps per channel calibration test

chart for our RGB and CMYK devices, the following would be

sufficient:

targen -v

-d2 -s50

-e3 -f0 PrinterA_c

targen -v

-d4 -s50

-e4 -f0 PrinterB_c

For an outline of how to then print and read the resulting test

chart, see Printing a print

profile test chart, and Reading

a print test chart using an instrument. Note that the printer

must be in an un-profiled and un-calibrated mode when doing this

print. Having done this, there will be a PrinterA.ti3 or

PrinterB.ti3 file containing the step wedge calibration chart

readings.

NOTE that if you are

calibrating a raw printer driver, and there is considerable dot

gain, then you may want to use the -p

parameter to adjust the test chart point distribution to spread them

more evenly in perceptual space, giving more accurate control over

the calibration. Typically this will be a value greater than one for

a device that has dot gain, e.g. values of 1.5, 2.0 or 2.5 might be

good places to start. You can do a preliminary calibration and use

the verbose output of printcal to recommend a suitable value for -p.

Creating a printer calibration

The printcal tool turns a calibration

chart .ti3 file into a .cal file. It has three main

operating modes:- Initial calibration, Re-Calibration, and

Verification. (A fourth mode, "Imitation" is very like Initial

Calibration, but is used for establishing a calibration target that

a similar printer can attempt to imitate.)

The distinction between Initial Calibration and Re-Calibration is

that in the initial calibration we establish the "aim points" or

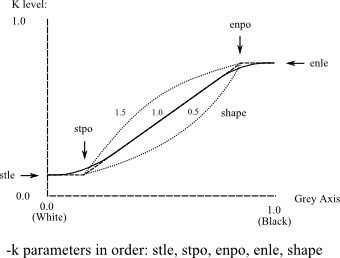

response we want out of the printer after calibration. There are

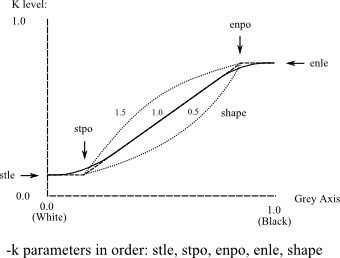

three basic parameters to set this for each channel: Maximum level,

minimum level, and curve shape.

By default the maximum level will be set using a heuristic which

attempts to pick the point when there is diminishing returns for

applying more colorant. This can be overridden using the -x# percent option, where # represents the choice of

channel this will be applied to. The parameter is the percentage of

device maximum.

The minimum level defaults to 0, but can be overridden using the -n# deltaE option. A minimum of

0 means that zero colorant will correspond to the natural media

color, but it may be desirable to set a non-pure media color using

calibration for the purposes of emulating some other media. The

parameter is in Delta E units.

The curve shape defaults to being perceptually uniform, which means

that even steps of calibrated device value result in perceptually

even color steps. In some situations it may be desirable to alter

this curve (for instance when non color managed output needs to be

sent to the calibrated printer), and a simple curve shape target can

be set using the -t# percent

parameter. This affects the output value at 50% input value, and

represents the percentage of perceptual output. By default it is 50%

perceptual output for 50% device input.

Once a device has been calibrated, it can be re-calibrated to the

same aim target.

Verification uses a calibration test chart printed through the

calibration, and compares the achieved response to the aim target.

The simplest possible way of creating the PrinterA.cal file is:

printcal -i PrinterA_c

For more detailed information, you can add the -v and -p flags:

printcal -v -p -i PrinterB_c

(You will need to select the plot window and hit a key to advance

past each plot).

For re-calibration, the name of the previous calibration file will

need to be supplied, and a new calibration

file will be created:

printcal -v -p -r PrinterB_c_old

PrinterB_c_new

Various aim points are normally set automatically by printcal, but these can be

overridden using the -x, -n and -t

options. e.g. say we wanted to set the maximum ink for Cyan to 80%

and Black to 95%, we might use:

printcal -v -p -i -xc 80

-xk 95 PrinterB_c

Using a printer calibration

The resulting calibration curves can be used with the following

other Argyll tools:

printtarg

To

apply

calibration

to

a

profile

test

chart,

and/or to have it included in .ti3 file.

cctiff

To

apply

color

management

and

calibration

to

an

image file.

applycal

To incorporate calibration into an ICC profile.

chartread

To

override

the

calibration

assumed

when

reading

a

profile chart.

In a workflow with native

calibration capability, the calibration curves would be used with

printarg during subsequent profiling

so that any ink limit calculations will reflect final device values,

while not otherwise using the calibration within the ICC workflow:

printtarg -v -ii1

-pA4 -I

PrinterA_c.cal PrinterA

This will cause the .ti2 and resulting .ti3 and ICC profiles to

contain the calibration curves, allowing all the tools to be able to

compute final device value ink limits. The calibration curves must

also of course be installed into the printer. The means to do this

is currently outside the scope of Argyll (ie. either the print

system needs to be able to understand Argyll CAL format files, or

some tool will be needed to convert Argyll CAL files into the

printer calibration format).

In a workflow without

native calibration capability, the calibration curves would be used

with printarg to apply

the calibration to the test patch samples during subsequent profiling, as well as embedding

it in the resulting .ti3 to allow all the tools to be able to

compute final device value ink limits:

printtarg -v -ii1

-pA4 -K

PrinterA_c.cal PrinterA

To apply calibration to an ICC profile, so that a calibration

unaware CMM can be used:

applycal PrinterA.cal PrinterA.icm PrinterA_cal.icm

To apply color management and calibration to a raster image:

cctiff Source.icm PrinterA.icm

PrinterA_c.cal infile.tif outfile.tif

or

cctiff Source.icm PrinterA_c.icm

infile.tif outfile.tif

[ Note that cctiff will also process JPEG raster images. ]

Another useful tool is synthcal, that

allows creating linear or synthetic calibration files for disabling

calibration or testing.

Similarly, fakeread also supports

applying calibration curves and embedding them in the resulting .ti3

file

If you want to create a pre-conditioning profile for use with targen -c, then use the PrinterA.icm

profile, NOT PrinterA_c.icm that has calibration curves

applied.

How profile ink limits are handled when

calibration is being used.

Even though the profiling process is carried out on top of the

linearized device, and the profiling is generally unaware of the

underlying non-linearized device values, an exception is made in the

calculation of ink limits during profiling. This is made possible by

including the calibration curves in the profile charts .ti2 and

subsequent .ti3 file and resulting ICC profile 'targ' text tag, by way of the printtarg -I or -K options. This is done on the assumption that the

physical quantity of ink is what's important in setting the ink

limit, and that the underlying non-linearized device values

represent such a physical quantity.

Linking Profiles

Two device profiles can be linked together to create a device link

profile, than encapsulates a particular device to device transform.

Often this step is not necessary, as many systems and tools will

link two device profiles "on the fly", but creating a device link

profile gives you the option of using "smart CMM" techniques, such

as true gamut mapping, improved inverse transform accuracy, tailored

black generation and ink limiting.

The overall process is to link the input space and output space

profiles using collink, creating a

device to device link profile. The device to device link profile can

then be used by cctiff (or other ICC device profile capable tools),

to color correct a raster files.

Three examples will be given here, showing the three different modes

than collink supports.

In simple mode, the two profiles are

linked together in a similar fashion to other CMMs simply using the forward

and backwards color transforms defined by the profiles. Any gamut

mapping is determined by the content of the tables within the two

profiles, together with the particular intent chosen. Typically the

same intent will be used for both the source and destination

profile:

collink -v

-qm -s -ip -op

SouceProfile.icm DestinationProfile.icm Source2Destination.icm

In gamut mapping mode, the

pre-computed intent mappings inside the profiles are not used, but

instead the gamut mapping between source and destination is tailored

to the specific gamuts of the two profiles, and the intent parameter

supplied to collink.

Additionally, source and destination viewing conditions should be

provided, to allow the color appearance space conversion to work as

intended. The colorimetric B2A table in the destination profile is

used, and this will determine any black generation and ink limiting:

collink -v

-qm -g -ip -cmt

-dpp MonitorSouceProfile.icm

DestinationProfile.icm Source2Destination.icm

[ If your viewing environment for the display and print doesn't

match the ones implied by the -cmt and

-dpp options, leave them out, and

evaluate what, if any appearance transformation is appropriate for

your environment at a later stage. ]

In inverse output table gamut mapping mode,

the pre-computed intent mappings inside the profiles are not used,

but instead the gamut mapping between source and destination is

tailored to the specific gamuts of the two profiles, and the intent

parameter supplied to collink.

In addition, the B2A table is not

used in the destination profile, but the A2B table is instead

inverted, leading to improved transform accuracy, and in CMYK

devices, allowing the ink limiting and black generation parameters

to be set:

For a CLUT table based RGB printer destination profile, the

following would be appropriate:

collink -v

-qm -G -ip -cmt

-dpp MonitorSouceProfile.icm

RGBDestinationProfile.icm Source2Destination.icm

For a CMYK profile, the total ink limit needs to be specified (a

typical value being 10% less than the value used in creating the

device test chart), and the type of black generation also needs to

be specified:

collink -v

-qm -G -ip -cmt

-dpp -l250

-kr MonitorSouceProfile.icm

CMYKDestinationProfile.icm Source2Destination.icm

Note that you should set the source (-c)

and destination (-d) viewing conditions

for the type of device the profile represents, and the conditions

under which it will be viewed.

Image dependent gamut mapping using device

links

When images are stored in large gamut colorspaces (such as. L*a*b*,

ProPhoto, scRGB etc.), then using the colorspace gamut as the source

gamut for gamut mapping is generally a bad idea, as it leads to

overly compressed and dull images. The correct approach is to use a

source gamut that represents the gamut of the images themselves.

This can be created using tiffgamut, and an example workflow is as

follows:

tiffgamut -f80 -pj -cmt ProPhoto.icm

image.tif

collink -v

-qh -G image.gam -ip

-cmt -dpp

ProPhoto.icm RGBDestinationProfile.icm Source2Destination.icm

cctiff Source2Destination.icm

image.tif printfile.tif

The printfile.tif is then send to the printer without color

management, (i.e. in the same way the printer characterization test

chart was printed), since it is in the printers native colorspace.

You can adjust how conservatively the image gamut is preserved using

the tiffgamut -f parameter. Omitting it or using a larger value (up

to 100) preserves the color gradations of even the lesser used

colors, at the cost of compressing the gamut more.

Using a smaller value will preserve the saturation of the most

popular colors, at the cost of not preserving the color gradations

of less popular colors.

You can create a gamut that covers a set of source images by

providing more than one image file name to tiffgamut. This may be

more efficient for a group of related images, and ensures that

colors are transformed in exactly the same way for all of the

images.

An alternative generating a gamut for a specific set of images, is

to use a general smaller gamut definition (i.e. the sRGB profile),

or a gamut that represents the typical range of colors you wish to

preserve.

The arguments to collink should be appropriate for the output device

type - see the collink examples in the above section.

Soft Proofing Link