In some situation there is no access to a displays VideoLUT

hardware, and this hardware is what is usually used to implement

display calibration. This could be because the display is being

accessed via a web server, or because the driver or windowing

system doesn't support VideoLUT access.

1) Don't attempt to calibrate, just profile the display.

2) Calibrate, but incorporate the calibration in some other

way in the workflow.

2a) Use dispcal to create a calibration and a quick profile

that incorporates the calibration into the profile.

2b) Use dispcal to create the calibration, then dispread and

colprof to create a profile, and then incorporate the calibration

into the profile using applycal.

2c) Use dispcal to create the calibration, then dispread and

colprof to create a profile, and then apply the calibration after

the profile in a cctiff workflow.

The first case requires nothing special, use dispcal in a normal

fashioned with the -o

option to generate a quick profile.The profile created will not contain a 'vcgt'

tag, but instead will have the calibration curves incorporated

into the profile itself. If calibration parameters are chosen that

change the displays white point or brightness, then this will

result in a slightly unusual profile that has a white point that

does not correspond with device R=G=B=1.0. Some systems may not

cope properly with this type of profile, and a general shift in

white point through such a profile can create an odd looking

display if it is applied to images but not to other elements on

the display say as GUI decoration elements or other application

windows.

In the second case, the calibration file created using dispcal

should be provided to dispread using the -K flag:

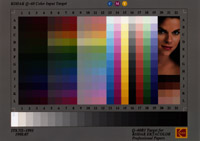

For an IT8.7/2 chart, this is the

ref/it8.cht file

supplied with Argyll, and the manufacturer will will supply

an individual or batch average file along with the chart

containing this information, or downloadable from their web site.

For instance, Kodak Q60 target reference files are

here.

NOTE that the reference file for the IT8.7/2 chart supplied with

Monaco EZcolor can be

obtained by unzipping the .mrf file. (You may have to make a copy

of the file with a .zip extension to do this.)

For the ColorChecker 24 patch chart, the

ref/ColorChecker.cht file

should be used, and there is also a

ref/ColorChecker.cie file provided that is based

on the manufacturers reference values for the chart. You can also

create your own reference file using an instrument and chartread,

making use of the chart reference file

ref/ColorChecker.ti2:

chartread -n -a

ColorChecker.ti2

Note that due to the small number of patches, a profile created

from such a chart is not likely to be very detailed.

For the ColorChecker DC chart, the

ref/ColorCheckerDC.cht file should be used, and

there will be a ColorCheckerDC reference file supplied by

X-Rite/GretagMacbeth with the chart.

The ColorChecker SG is relatively expensive, but is preferred by

many people because (like the ColorChecker and ColorCheckerDC) its

colors are composed of multiple different pigments, giving it

reflective spectra that are more representative of the real world,

unlike many other charts that are created out of combination of 3

or 4 colorants.

A limited CIE reference file is available from X-Rite

here,

but it is not in the usual CGATS format. To convert it to a CIE

reference file useful for

scanin,

you will need to edit the X-Rite file using a

plain text editor,

first deleting everything before the line starting with "A1" and

everything after "N10", then prepending

this

header, and appending

this footer,

making sure there are no blank lines inserted in the process.

If you do happen to have access to a more comprehensive instrument

measurement of the ColorChecker SG, or you have measured it

yourself using a color instrument,

then you

may

need to convert the reference information from spectral

ColorCheckerSG.txt file to CIE

value

ColorCheckerSG.cie

reference file, follow the following steps:

txt2ti3

ColorCheckerSG.txt ColorCheckerSG

spec2cie

ColorCheckerSG.ti3 ColorCheckerSG.cie

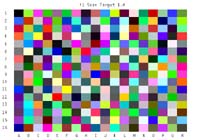

For the Eye-One Pro Scan Target 1.4 chart, the

ref/i1_RGB_Scan_1.4.cht

file should be used, and as there is no reference file

accompanying this chart, the chart needs to be read with an

instrument (usually the Eye-One Pro). This can be done using

chartread, making use of the chart reference file

ref/i1_RGB_Scan_1.4.ti2:

chartread -n -a

i1_RGB_Scan_1.4

and then rename the resulting

i1_RGB_Scan_1.4.ti3

file to

i1_RGB_Scan_1.4.cie

For the HutchColor HCT chart, the

ref/Hutchcolor.cht

file should be used, and the reference

.txt file downloaded from the HutchColor website.

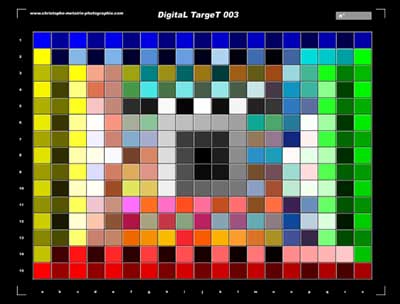

For the Christophe Métairie's Digital TargeT 003 chart with

285 patches, the

ref/CMP_DT_003.cht

file should be used, and the cie reference

files come with the chart.

For the Christophe Métairie's Digital Target-3 chart with

570 patches, the

ref/CMP_Digital_Target-3.cht

file should be used, and the cie reference

files come with the chart.

For the LaserSoft DCPro chart, the

ref/LaserSoftDCPro.cht file should be used, and

reference

.txt file

downloaded from the

Silverfast

website.

For the Datacolor SpyderCheckr, the

ref/SpyderChecker.cht file should be used, and a

reference

ref/SpyderChecker.cie

file made from measuring a sample chart is also available.

Alternately you could create your own reference file by

transcribing the

values

on the Datacolor website.

For the QPCard 201, the

ref/QPcard_201.cht

file should be used, and a reference

ref/QPcard_201.cie file made from measuring a

sample chart is also available.

For the QPCard 202, the

ref/QPcard_202.cht

file should be used, and a reference

ref/QPcard_202.cie file made from measuring a

sample chart is also available.